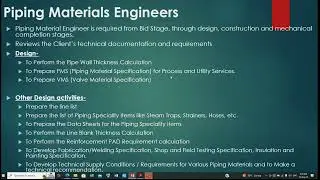

Introduction Basics of ASME B31 3 for a Piping Stress Engineer

ASME B31.3 is the Process Piping Code for Process Piping Engineers. This is also known as the Process Piping Bible. The aim of this course is to help process piping engineers learn the aspects of pipe stress analysis from the Code. Studying the full code and understanding the stress analysis basics from the code usually takes a lot of time. In this course, the main important points from the code are highlighted and presented in an easy-to-understand way. However, this course does not substitute the Process Piping Code. For in-depth learning, you must refer to the original ASME B31.3 code.

Most of the pipe stress analysis software packages use the data from ASME B31.3 to calculate stresses as per the code equations and allowable. The material allowable values with respect to temperature are also provided in the Code. So, all piping stress engineers must have a preliminary knowledge of the code. This course explains some of the important aspects of the ASME B31.3 that will be useful to piping stress engineers.

ASME B31.3 is very important to piping stress engineers because:

ASME B31.3 is important for piping stress engineers because it provides the guidelines and requirements for designing and analyzing process piping systems. Piping stress engineers are responsible for ensuring that piping systems can withstand the loads and stress that they will be subjected to during normal operation, as well as under abnormal conditions such as earthquakes or thermal expansion.

ASME B31.3 provides the necessary information on material selection, design, fabrication, assembly, inspection, testing, and maintenance of process piping systems. It is the primary code used in the United States for piping design and construction, and it is recognized globally as a standard for process piping systems.

By following the guidelines and requirements of ASME B31.3, piping stress engineers can ensure that piping systems are designed and constructed to be safe, reliable, and efficient. Compliance with the code is often required by regulatory agencies, and failure to comply can result in costly legal and safety issues.

Furthermore, piping stress engineers need to be familiar with ASME B31.3 in order to perform accurate and reliable stress analysis of piping systems. The code provides the necessary input data and formulas for calculating the stresses and loads that piping systems will be subjected to, and it outlines the procedures for evaluating the results of stress analysis.

Enroll : https://www.everyeng.com/learn/course...

Many More Courses

Caesar II Pipe Stress Analysis Basic Course

Enroll: https://www.everyeng.com/learn/course...

Slug Flow Analysis in Caesar II (Both Static and Dynamic)

Enroll: https://www.everyeng.com/learn/course...

Basics of Pipe Stress Analysis

Enroll: https://www.everyeng.com/learn/course...

Pressure Relief Valve Piping Stress Analysis

Enroll: https://www.everyeng.com/learn/course...

Flow Induced Vibrations for Piping Systems

Enroll: https://www.everyeng.com/learn/course...

FRP Pipe Stress Analysis with Caesar II

Enroll: https://www.everyeng.com/learn/course...

Simplifying ASME B31.3 for a Pipe Stress Engineer

Enroll: https://www.everyeng.com/learn/course...

Steps for Reviewing a Pipe Stress Analysis Report

Enroll: https://www.everyeng.com/learn/course...

Get Started via https://everyeng.com/home

@EveryEng Engineers’s Ecosystem creates Opportunities to Learn, Earn and Grow! At @EveryEng we believe YOU are important, so we leave it to you what you want to browse and participate. All in one ecosystem so you can browse as per your interest and participate where you get maximum value. @EveryEng - Mechanical is created to support Mechanical Engineering Students & Beginners

Linkedin Profile

/ everyeng

Join our whatsapp group

https://chat.whatsapp.com/K2k0snzvGVD...

Join our telegram channel for books and pdf

https://t.me/everyeng

#mechanical

#engineering

#thermal

#everyeng

#science

#technology

#edtech

#chemical

Watch video Introduction Basics of ASME B31 3 for a Piping Stress Engineer online, duration hours minute second in high quality that is uploaded to the channel EveryEng - Mechanical 21 July 2024. Share the link to the video on social media so that your subscribers and friends will also watch this video. This video clip has been viewed 207 times and liked it 2 visitors.